Products / Ceramic heating elements / Wafer heaters

Wafer heaters

General description:

The full-ceramic heating elements made from silicon nitride by Bach RC are very suitable for use in semiconductor production plants, especially for wafer bonding: The ceramic heating elements are ground to very good flatness and parallelism. The low thermal expansion of silicon nitride ensures that even at high temperatures, this good flatness and parallelism is preserved and only minimum thermal distortion appears. In addition, the thermal expansion of silicon nitride is well in line with that of silicon, so that also, hardly any relative movement takes place between the wafer and the heating element while heating. Together with the very high-pressure resistance of the ceramic heaters, these properties form the basis for optimum bond homogeneity. The heating close to the wafer makes it possible to keep the thermal mass to be heated low, so that short cycle times and therefore high productivity can be realised. Bach RC offers heating plates for the typical wafer formats, in particular 4"/6"/8" and 12" as standard sizes. We are happy to develop and manufacture other sizes, up to 450 mm diameter, or a special layout of the heating plates, custom-designed for you. Various equipment features can therefore be integrated: Through holes for lift pins, boreholes for integrated temperature sensors, vacuum chuck function, cooling function, design with several separately adjustable heating circuits for optimising the temperature homogeneity, electrostatic discharge from the plate surface, and elements for fixing the heating plate.

Basic values:

| Parameter | Value |

|---|---|

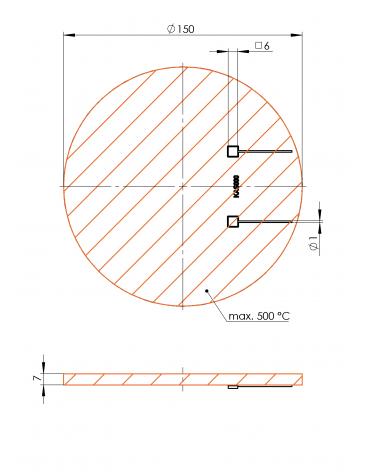

| Dimensions | Ø 150 x 7.0 mm |

| Heated area | Ø 150 x 7.0 mm |

| Tmax | 500 °C |

| Remark | - |

Details:

- Standard

-

Description

* The actual power depends on resistance, temperature and voltage.

Parameter Value Article no. FLR 100 030 Resistance @ 20 °C 26.5 Ω ±25 % Nominal voltage 230 V Nominal power @ 20 °C 2 000 W*